Scissor Lift Introduction:

A scissor lift, a scissor lifting platform, is a versatile hydraulically driven lifting device designed to lift people and heavy objects vertically. The main feature of a scissor lift is its longitudinal and transverse support mechanism that extends and retracts to provide a stable, safe platform for various applications.

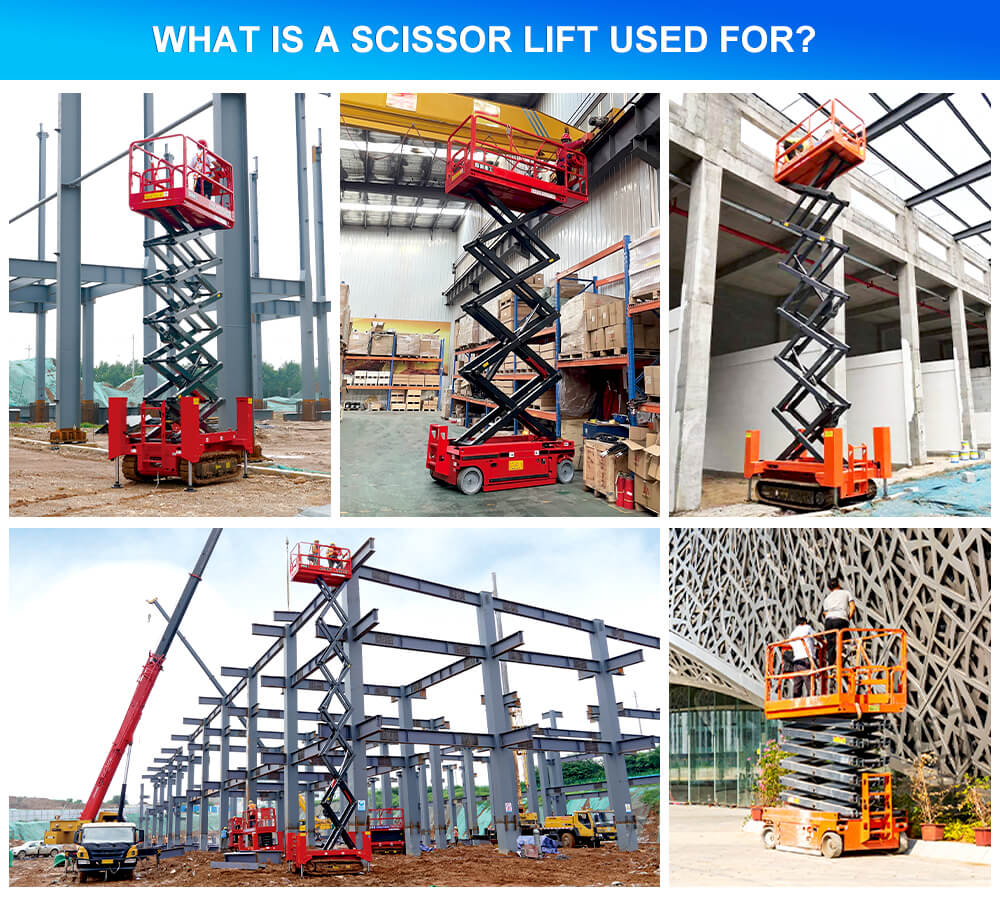

Typical working environments for scissor lifts:

Scissor lifts are often used in a variety of work environments, including:

Construction sites: Scissor lifts are critical for painting, electrical work, and accessing elevated structures, providing a safe and stable working platform.

Warehouses and distribution centers: In these environments, scissor lifts help optimize storage and logistics by stacking and retrieving goods on high racks.

Maintenance and Repair: Industries such as automotive, aviation, and facility management rely on scissor lifts for efficient maintenance, repair, and inspection of equipment and infrastructure.

Retail: Scissor lifts assist retailers in storing and retrieving products on high shelves, ensuring efficient inventory management.

Events and entertainment: The entertainment industry utilizes scissor lifts for stage setups, lighting setups, and other event-related activities.

How should we choose a scissor lift?

Lift Capacity:

Consider how heavy loads your scissors will carry before making your selection. Lift capacities differ between models, so you must find one capable of supporting anticipated maximum loads, such as workers, tools, or materials. Hence, your lift operates within its stated capacity.

Platform Size and Working Heights:

Assess the required platform size and working height for your tasks. Make sure the scissor lift you select provides sufficient room for workers and materials while reaching their intended working height, taking both extended and retracted dimensions into consideration for accessibility in tight spaces.

Scissor lifts are equipped with three power sources – electric, diesel, and hybrid models are available – for indoor and outdoor applications. Electric charges produce no emissions while operating quietly, while diesel lifts offer increased power and rough-terrain capability; hybrid models combine benefits from both sources for optimal operation.

Mobility and Terrain: Consider where your scissor lift will operate when selecting its appropriate model. If tasks involve working on rough or uneven surfaces, go for something with puncture-resistant tires and excellent ground clearance; some lifts have even been explicitly designed to be used outdoors as they offer increased stability on challenging terrains.

Prioritize safety features to safeguard operators and workers. Look for lifts equipped with guardrails, safety interlocks, emergency lowering systems, and overload protection to create an atmosphere conducive to working safely in an office environment. An understanding of safety features helps provide for an ideal working environment.

Ease of Maintenance: For maximum operational efficiency and reduced downtime, consider choosing a scissor lift equipped with user-friendly maintenance features such as easy access to components, intuitive control systems, and straightforward procedures for routine servicing and upkeep. Such features could contribute significantly towards reduced operational timeframes and greater uptime efficiency.

Budget Considerations: Finally, assess and compare costs between scissor lift models when considering your budget constraints and associated costs. Be mindful of the initial purchase price and ongoing maintenance and operational expenses when making this choice; striking an equitable balance between quality and price ensures an affordable yet reliable solution.

Do I need certification to use a scissor lift?

Aerial Work Platform (AWP) Certification:

One of the primary certifications available to scissor lift operators is Aerial Work Platform Certification, or AWP for short. This program equips operators with a solid understanding of safely operating various elevated work platforms – including scissor lifts – covering equipment controls, emergency procedures, and hazard recognition.

OSHA Training for Aerial Lift Operators (AOSA Training):

OSHA mandates OSHA-accredited training programs for those operating aerial lifts, such as scissor lifts. Training includes OSHA regulations related to lift operations, such as hazard identification, fall protection measures, and proper use of personal protective equipment (PPE). OSHA Training ensures compliance with national safety standards.

Manufacturer-Specific Training: Operators should secure training from the scissor lift manufacturer to gain in-depth knowledge of its features, controls, and maintenance requirements for safe and efficient performance. Such knowledge is vitally important.

Due to the elevated nature of scissor lift work, operators must receive proper fall protection training. This certification includes using guardrails, personal fall arrest systems, and other measures designed to prevent falls from elevated platforms – this training serves an integral purpose in maintaining operator safety at height.

Emergency Evacuation and Rescue Training:

Operators should receive proper emergency evacuation and rescue training specific to scissor lifts, including how to lower their platform safely in case of power outages or malfunctions. Training provides fast response in times of troubleshooting emergencies.

Well-known brands (including CFMG)

When discussing prominent brands, CFMG (Shandong Chufeng Heavy Industry Group Co., Ltd.) stands out as one of China’s largest scissor lift manufacturers, boasting a 15-year history. Known for their robust cost-efficiency and durable products, CFMG has gained recognition worldwide for their exceptional value. Other well-known brands in the industry include Genie, JLG, Skyjack, Haulotte, Snorkel, etc.

Price range:

Scissor lift prices vary widely depending on lifting capacity, platform height, power source, and brand. Fees range from a few thousand dollars for smaller, basic models to tens of thousands for more extensive, high-capacity units with advanced features. CFMG and other manufacturers offer models in various price ranges to meet different budgets.

Scissor lift applications:

Scissor lifts are versatile and suitable for a wide range of tasks in a variety of industries, such as:

Construction: Enabling safe operation at height for construction, maintenance, and installation activities.

Warehousing and logistics: to optimize material handling, storage, and retrieval.

Facility maintenance: providing access for routine maintenance and repair.

Retail: Support efficient inventory management by reaching high shelves.

Entertainment and Events: Facilitate stage and lighting setups during concerts, shows, and events.

Emergency Services: assisting with rescue operations and access to upland areas in an emergency.

In short, scissor-type aerial work platforms are valuable equipment with multiple applications across industries. They come in various specifications, brands, and prices, allowing them to be adapted to specific job requirements and budgets. They ensure safe and efficient access to elevated work areas and materials.

Post time: Oct-21-2023